The AIRKEG by ROLAIR®

MORE AIR. LESS HASSLE.

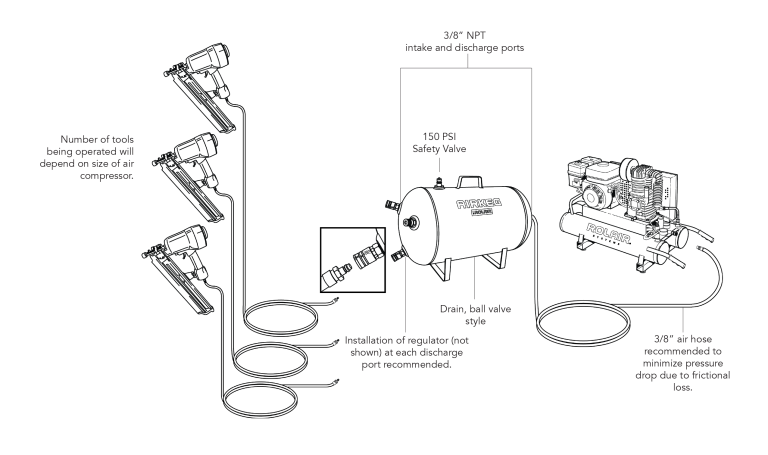

The AIRKEG by ROLAIR® works with your existing pneumatic set-up to increase reserve air and minimize frictional loss over extended distances. The illustration below shows a basic configuration.

This is an example of a simple configuration. Multi-coupler manifolds can be utilized to increase the number of tools that get plugged into each port. Keep in mind that the CFM requirement of all tools being operated must not exceed the delivered CFM rating of the air compressor.

THE AIRKEG ADVANTAGE.

Adding an auxiliary tank to your existing pneumatic system provides several advantages.

- The first is that it provides users with more air, which prevents the air compressor from cycling too often.

- The second advantage is that, by bringing a supplementary air supply closer to the tool, the user can work farther from the air compressor. This makes for a quieter, safer work environment.

- Last but not least, additional air means consistent pressure to the tool for longer periods of time. This can result in fewer ‘stair-stepped’ nails.

If you have any questions about how an auxiliary tank can benefit your crew, drop us a line. Already convinced? Contact your local ROLAIR dealer or go online to get yours.